What is ISO 9001?

THE BASICS

What is ISO 9001?

What does ISO 9001 stand for? ISO 9001 is the international standard for creating a Quality Management Systems (QMS), published by ISO (the International Organization for Standardization). The standard was most recently updated in 2015, and it is referred to as ISO 9001:2015. In order to be released and updated, ISO 9001 had to be agreed upon by a majority of member countries so that it would become an internationally recognized standard, which means it is accepted by a majority of countries worldwide.

What are quality management systems? An ISO 9001 definition would be that this standard provides the QMS requirements to be implemented for a company that wants to create all of the policies, processes, and procedures necessary to provide products and services that meet customer and regulatory needs and improve customer satisfaction. Quality management systems are the foundation of quality assurance activities.

Why is ISO 9001 important?

As stated above, ISO 9001:2015 is an internationally recognized standard for creating, implementing, and maintaining a Quality Management System for a company. It is intended to be used by organizations of any size or industry, and it can be used by any company. As an international standard, it is recognized as the basis for any company to create a system to ensure customer satisfaction and improvement and, as such, many corporations require this certification from their suppliers.

ISO 9001 certification provides your customers reassurance that you have established a Quality Management System based on the seven quality management principles of ISO 9001. To learn more about the quality management principles behind the ISO 9001 standard, take a look at this article: Seven Quality Management Principles behind ISO 9001 requirements.

In fact, ISO 9001 is such an essential and influential standard that it is used as the basis when industry groups want to create their own industry standards; this includes AS9100 for the aerospace industry, ISO 13485 for the medical devices industry, and IATF 16949 for the automotive industry.

A survey of ISO 9001 certification at the end of 2017 shows that, in spite of the global recession, the number of companies that have implemented the ISO 9001 quality management standard still remains stable worldwide. Below are the results over the previous six-year period.

What is the current ISO 9001 standard?

The current revision of the standard is ISO 9001:2015. The ISO 9001 2015 standard, sometimes called ISO 9001 revision 2015, was released in October 2015 and replaced the previous revision ISO 9001:2008. This updated revision includes many of the processes from the previous revision of the standard, with a greater focus on risk-based thinking and understanding the context of the organization. To support this change, there was a major structural change from the ISO 9001:2008 standard – the main clauses of the standard are different between the 2015 and 2008 revisions.

What is ISO 9001:2008?

ISO 9001:2008 is the revision of the ISO 9001 standard that was withdrawn in 2015. ISO 9001:2008 was based on its predecessor, ISO 9001:2000, with some minor additions. ISO 9001:2000 was the first revision of the ISO 9001 standard to be based on the seven quality management principles identified above that made the standard requirements about everything a company does to create products and services. Revisions of ISO 9001 before the ISO 9001:2000 revision (ISO 9001:1987 & ISO 9001 1994) were based more on writing and following 20 specific procedures, rather than understanding the processes of the organization.

ISO 9000 vs ISO 9001

While ISO 9001:2015 is the current ISO standard for creating a Quality Management System, there are other documents in the ISO 9000 family that support the ISO 9001 requirements. ISO 9000 explains the seven quality management principles behind ISO 9001, and defines all of the terms used within the ISO 9001 standard. Additionally, ISO 9004 provides guidance on making an ISO 9001 Quality Management System more successful and focuses on how to improve the implemented ISO 9001 processes by giving some best practice information.

What is the purpose of ISO?

With all of this talk about ISO standards, it is common to wonder what ISO is all about. The International Organization for Standardization (referred to as ISO, as this is the Greek word for “the same”) is an international organization that creates standard sets of requirements and guidelines to help organizations around the world to act in a more consistent manner. The ISO organization develops, publishes, and maintains more than 22,450 standards through technical committees that include members from all over the world. These standards provide information on how to design and build products, perform specific testing, and create management systems.

It is important to note that the ISO does not provide certification or conformity auditing or assessment. The ISO is strictly involved in the maintenance of the standards, and it leaves the assessment of companies against the standards to external certification bodies.

What are the ISO 9001 requirements?

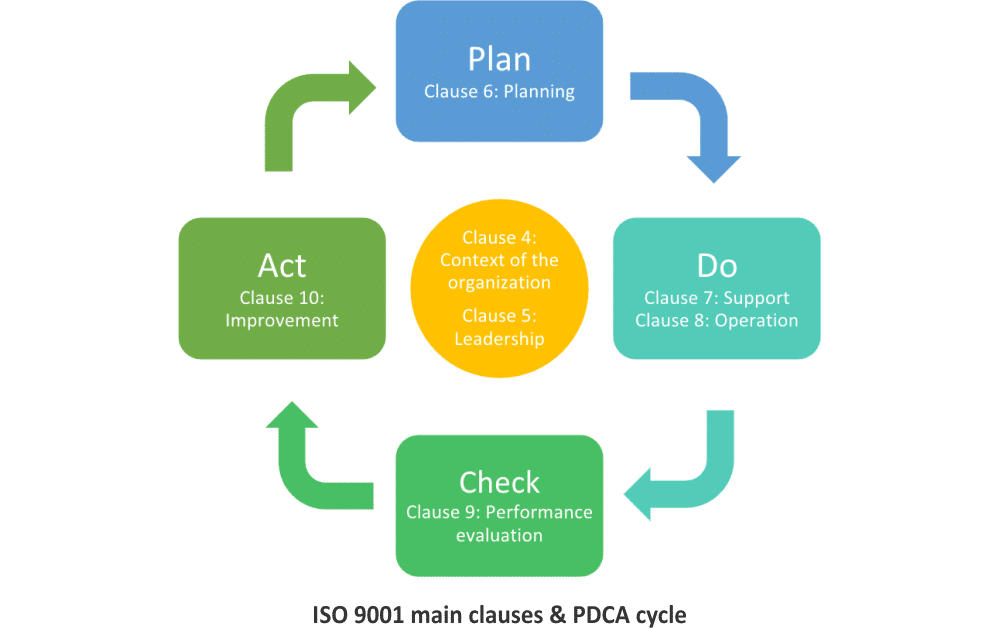

The structure of the ISO 9001:2015 standard is split into 10 sections (clauses). The first three are introductory, while the last seven contain the requirements for the Quality Management System against which a company can be certified. Here is what the seven main clauses are about:

Clause 4: Context of the organization – This section talks about requirements for understanding your organization in order to implement a QMS. It includes the requirements for identifying internal and external issues, identifying interested parties and their expectations, defining the scope of the QMS, and identifying your processes and how they interact. Expectations of interested parties include regulatory requirements as well.

Clause 5: Leadership – The leadership requirements cover the need for top management to be instrumental in the implementation of the QMS. Top management needs to demonstrate commitment to the QMS by ensuring customer focus, defining and communicating the quality policy, and assigning roles and responsibilities throughout the organization.

Clause 6: Planning – Top management must also plan for the ongoing function of the QMS. Risks and opportunities of the QMS in the organization need to be assessed, and quality objectives for improvement need to be identified and plans made to accomplish these objectives.

Clause 7: Support – The support section deals with the management of all resources for the QMS, covering the necessity to control all resources, including human resources, buildings and infrastructure, the working environment, monitoring and measurement resources, and organizational knowledge. The section also includes requirements around competence, awareness, communication, and controlling documented information (the documents and records required for your processes).

Clause 8: Operation – The operation requirements deal with all aspects of the planning and creation of the product or service. This section includes requirements on planning, product requirements review, design, controlling external providers, creating and releasing the product or service, and controlling nonconforming process outputs.

Clause 9: Performance evaluation – This section includes the requirements needed to make sure that you can monitor whether your QMS is functioning well. It includes monitoring and measuring your processes, assessing customer satisfaction, internal audits, and ongoing management review of the QMS.

Clause 10: Improvement – This last section includes the requirements needed to make your QMS better over time. This includes the need to assess process nonconformity and taking corrective actions for processes.

These sections are based on the Plan-Do-Check-Act cycle, which uses these elements to implement change within the processes of the organization in order to drive and maintain improvements within the processes.

What is a quality management system?

The Quality Management System, which is often referred to as a QMS, is a collection of policies, processes, documented procedures, and records. This collection of documentation defines the set of internal rules that will govern how your company creates and delivers your product or service to your customers. The QMS must be tailored to the needs of your company and the product or service you provide, but the ISO 9001 standard provides a set of guidelines to help make sure that you do not miss any important elements that a QMS needs to be successful.

How is ISO 9001 implemented?

Starting with management support and identifying the customer requirements for the QMS, you will need to start with defining your quality policy and quality objectives, which together define the overall scope and implementation of the Quality Management System. Along with these, you will need to create the mandatory and additional processes and procedures necessary for your organization to properly create and deliver your product or service. There are six mandatory documents that need to be included, and others to be added as the company finds them necessary.